Developing prototypes for model based software solution for controlling the Sawyer robot arm. This enables a smoother human robot workflow for people working in a social work place.

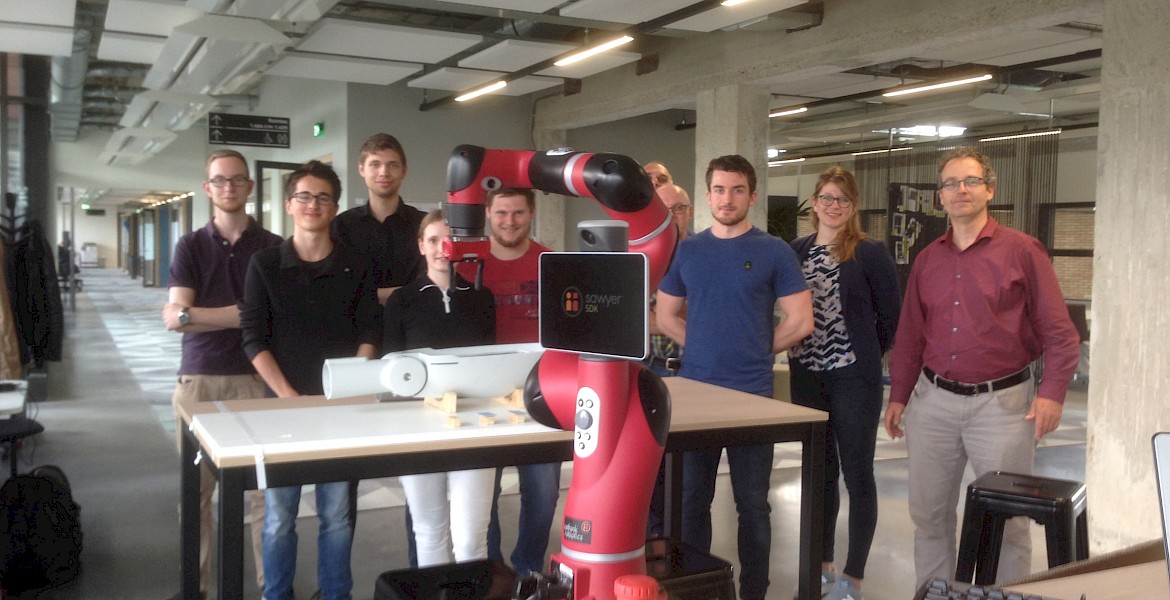

Two student groups of semester 6 ICT & Technology education and one intership student ICT & Technology worked on the Sawyer robot arm in first half of 2019. They worked on the Amfors case: to position LED-devices in a street armature. Amfors is a company for sheltered employment in Amersfoort and partner in the Close Encounters project.

The semester 6 students worked on a ROS- and model based software solution for the Cobot that should support the workforce at Amfors to do their job. The developed solution positions the LED accurately and robust in the armature. The LED has to be glued in the armature. The modeling approach is done by using FlexBE which is a ROS-way of modeling state behavior. FlexBE was applicable to define the workflow at Amfors, defining process steps like: object picking, moving. The student projects proof the ability to controlling the Sawyer arm via the ROS level and over network. This should enable us to develop the application in a customizable way focused on the End-user (= the operators at Amfors) needs. Future work is planned on integrating the GUI and FlexBE approach, the GUI for close interaction with the human workflows and FlexBE for operating the workflows.