About

Disassembly is about separating products, to get a product decomposed in its parts. It is a phase when remanufacturing, refurbishing or recycling a product. We perceive disassembly as an vital activity when reducing dependencies on critical raw materials and to reduce carbon footprint of manufacturing.

We observe that companies in the manufacturing industry are faced with the challenge of making their production and materials more sustainable. Sometimes the disassembly of a product is perceived as easy when part are just clicked together. Sometimes the disassembly is more difficult when parts are glued together, and also when thinking about how to determine and guarantee the status of the product components. Apart from the technical challenges

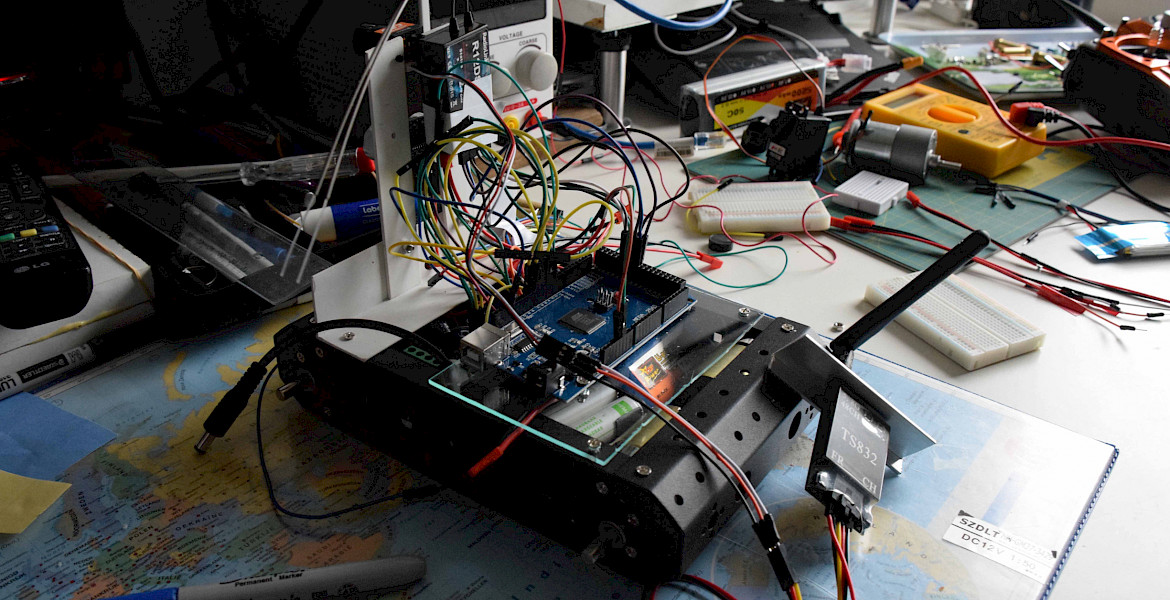

The focus of our research is to apply ICT methods and tools to identify relationships between product characteristics and the processes to enable product disassembly.

Identification of product characteristics – Smart technologies might help to gain a better understanding of devices and to keep an overview of their life cycle. An example of such a technology is the Asset Administration Shell (AAS) to describe a physical device or machine (asset) through a digital shell around it as well as to make the actions that it does on the product that it (dis)assembles traceable. In the end the a digital twin of the device is producible. The research group organizes an (online) mini course where we explain how an AAS is drawn up. We do this on the basis of a specific device, namely the heating devices: a central heating boiler and heat pump.

One of the assets to work on disassembly is our Sawyer robot arm. Find Kris and Edwin working on the Sawyer.

We work together with other research groups in the Netherlands, in the "lectoren platform Sustainable Smart Industry - Disassembly" The research groups are:

- Circular Plastics/Smart Sustainable Manufacturing (NHL Stenden)

- Digital Business & Society/Industriële Automatisering (Hogeschool Windesheim)

- Smart Sustainable Manufacturing (Haagse Hogeschool)

- Lean & World Class Performance (Hogeschool Arnhem Nijmegen)

- High Tech Embedded Software (Fontys Hogeschool)